In any electrical installation, cable containment systems play a crucial role in safely organizing and routing cables. These systems not only keep cables neat but also protect them from damage and environmental factors. Choosing the right containment system depends on factors like budget, building design, and the type of cables used.

In this post, we’ll explore common types of cable containment systems, how they are used, and key points to consider when selecting the right one for your project.

What is a Cable Containment System?

A cable containment system manages and protects electrical wiring within a building. These systems are essential in industrial, commercial, and residential settings. They prevent damage, ensure safety, and help meet regulations. The choice of system depends on factors like cable weight, type, environmental conditions, and building infrastructure.

Let’s take a look at the most popular types of cable containment systems.

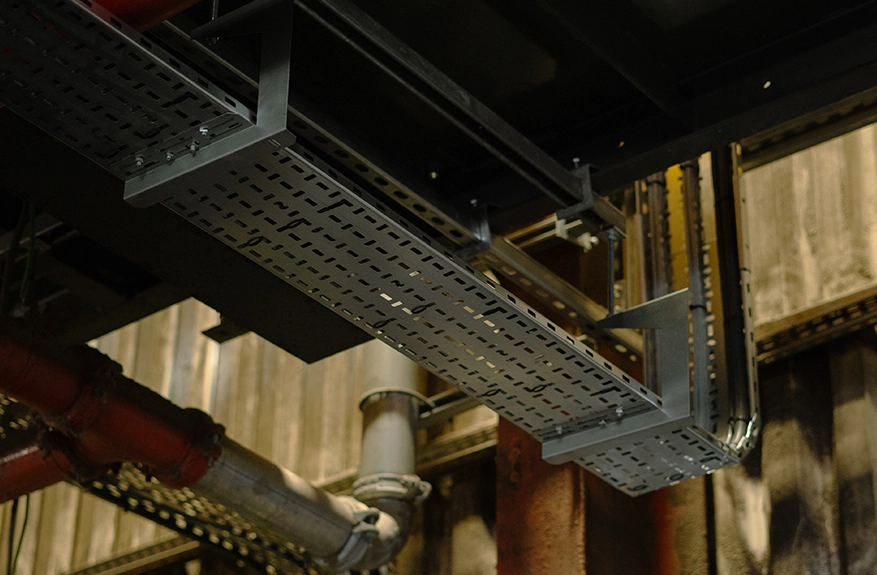

1. Cable Trays

Cable trays are one of the most widely used systems for managing large amounts of wiring. Made from materials like galvanized steel or aluminum, they provide sturdy support for cables in both horizontal and vertical setups. These trays are ideal for industrial and commercial environments that require high-capacity wiring.

Benefits:

- Efficiently support large numbers of cables.

- Allow easy changes or additions to wiring.

- Promote air circulation, reducing cable overheating.

Applications:

- Factories

- Data centers

- Commercial buildings

2. Conduits

Conduits protect electrical cables by routing them through tubes made of metal, plastic, or composites. These tubes shield wiring from moisture, dust, and damage, making them perfect for outdoor or industrial environments.

Types of Conduits:

- Rigid Metal Conduit (RMC): Used in industrial areas where strong protection is needed.

- PVC Conduit: Lightweight and corrosion-resistant, ideal for moisture-prone areas.

Benefits:

- Provide excellent physical protection.

- Make it easy to replace or upgrade wiring.

- Allow pre-installed wiring drops for future equipment.

Applications:

- Industrial plants

- Hospitals

- Moisture-prone environments

3. Trunking

Trunking offers a flexible solution for routing insulated cables. Made from PVC, steel, or aluminum, it can be bent and joined to fit around corners and architectural features, making it useful in complex installations. Trunking systems are rated by their Ingress Protection (IP) Code, which measures protection against dust and water.

Benefits:

- Highly flexible for routing cables.

- Modular design makes it easy to adjust or reroute cables.

- Available in various IP ratings for different environments.

Applications:

- Office buildings

- Commercial premises

- Schools

Choosing the Right System

When selecting a cable containment system, it’s important to consider the environment, type of cables, and load capacity. The right system ensures safety, simplifies maintenance, and supports future expansions.

Whether you’re working on an industrial site or a small commercial project, proper cable containment is key to safety, compliance, and reliability. For expert advice on choosing the right system, contact One Way Group. Our experienced engineers specialize in designing and installing custom cable management solutions.